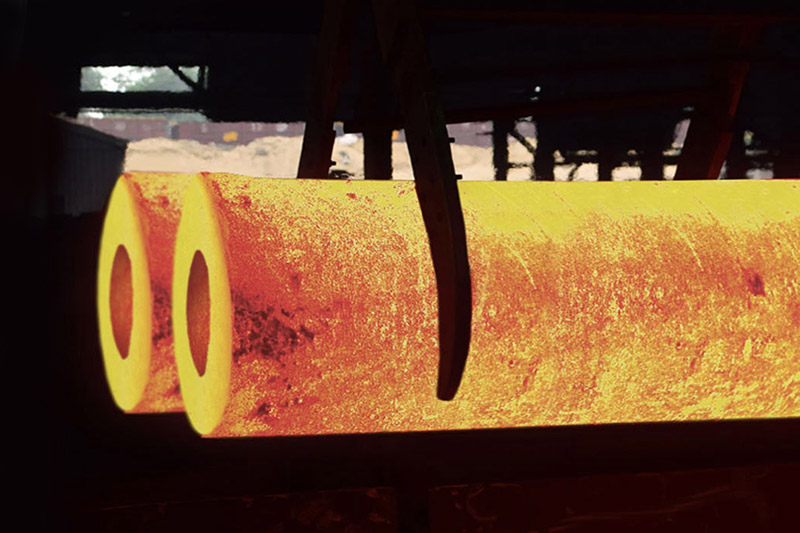

600mm HP Graphite Electrode

What we offer

Our main products are Graphite electrode, CPC and DPC, graphite crucible, special graphite, graphite electrode joint, etc.

Production equipment

We have full-automatic dispensing system, 3500 tons elec-trode forming extruder, CNC machining machine and international advanced sub processing automatic line and advanced detection equipment.

Process flow

Henan KFCC Carbon Co.,Ltd. covers an area of about 130,000 square meters with total assets 350 million Yuan, which is a high-tech private enterprise. We mainly engaged in graphite electrode, graphite cru-cible, Special carbon-graphite material etc. Annual production of graphite products is 20,000 tons.

Professional graphite electrode

Henan KFCC Carbon Co.,Ltd. covers an area of about 130,000 square meters with total assets 350 million Yuan, which is a high-tech private enterprise. We mainly engaged in graphite electrode, graphite cru-cible, Special carbon-graphite material etc. Annual production of graphite products is 20,000 tons.

Strong production strength

We have full-automatic dispensing system, CNC machining machine and advanced detection equipment, etc.

Strict quality inspection

We have advanced testing equipment to ensure the quality of products from raw materials to finished products.

Extensive sales network

Based on good faith and win-win cooperation, we are willing to provide quality service and quality products.

Our certificates

Our main products are Graphite electrode, CPC and DPC, graphite crucible, special graphite, graphite electrode joint, etc.

Do You Have any Questions?

Submit a business inquiry online or visit the nearest service consulting office.

Industrial graphite is hard and brittle, and it wears more severely to the tool during CNC machining. Generally, it is recommended to use carbide or diamond coated tools. When roughing graphite, the tool can be directly up and down on the workpiece. In order to avoid chipping and chipping during finishing, it is often processed with a light tool and fast walking. -Generally speaking, graphite seldom breaks when the cutting depth is less than 0.2mm. A better sidewall surface quality will be obtained. The dust generated during CNC machining of graphite electrodes is relatively large, which may invade the guide screw and spindle of the machine tool. This requires the graphite processing machine tool to have a corresponding device for processing graphite dust, and the machine tool must have good sealing performance, because graphite is poisonous.

The production of professional graphite electrodes is mainly processed by high-speed machine tools. The stability of the machine tools should be good, the three-axis movement should be uniform and stable without vibration, and the rotation accuracy of the spindle should be as good as possible. Graphite electrodes are carbon electrodes. Because graphite has good electrical conductivity, it can save a lot of time in electrical discharge machining, which is one of the reasons why graphite is used as an electrode.

1. The CNC machining speed is fast, the machinability is high, and the trimming is easy

2. Fast EDM forming, small thermal expansion, low loss

3. Lightweight and low cost

Used in electric arc steelmaking furnaces, submerged electric furnaces, resistance furnaces as conductive electrodes, a large number of graphite electrode blanks are also used to process various crucibles, graphite boats, hot die casting molds and vacuum electric furnace heating elements and other special-shaped products.

Graphite electrode is a kind of high temperature resistant graphite conductive material, which can be divided into: ordinary power graphite electrode (RP); high power graphite electrode (HP); quasi-super high power graphite electrode (SHP); ultra high power graphite electrode (UHP).

Follow us on social media

©2021 Henan KFCC Carbon Co.,Ltd. all rights reserved

What We Offer

Contact Info

EMAIL:

Cellphone:

+86-13937818638/ +86-13930977267

Address:

Kaifeng City, Henan Province, China(Mainland)

admin@kfcccarbon.com

admin@kfcccarbon.com

+86-18831976760

+86-18831976760