Contact us

Add: No.003 Dongjiao Industrial Park, Kaifeng City, Henan Province, China(Mainland)

Tel: +86-13937818638 / +86-13930977267

Email: admin@kfcccarbon.com

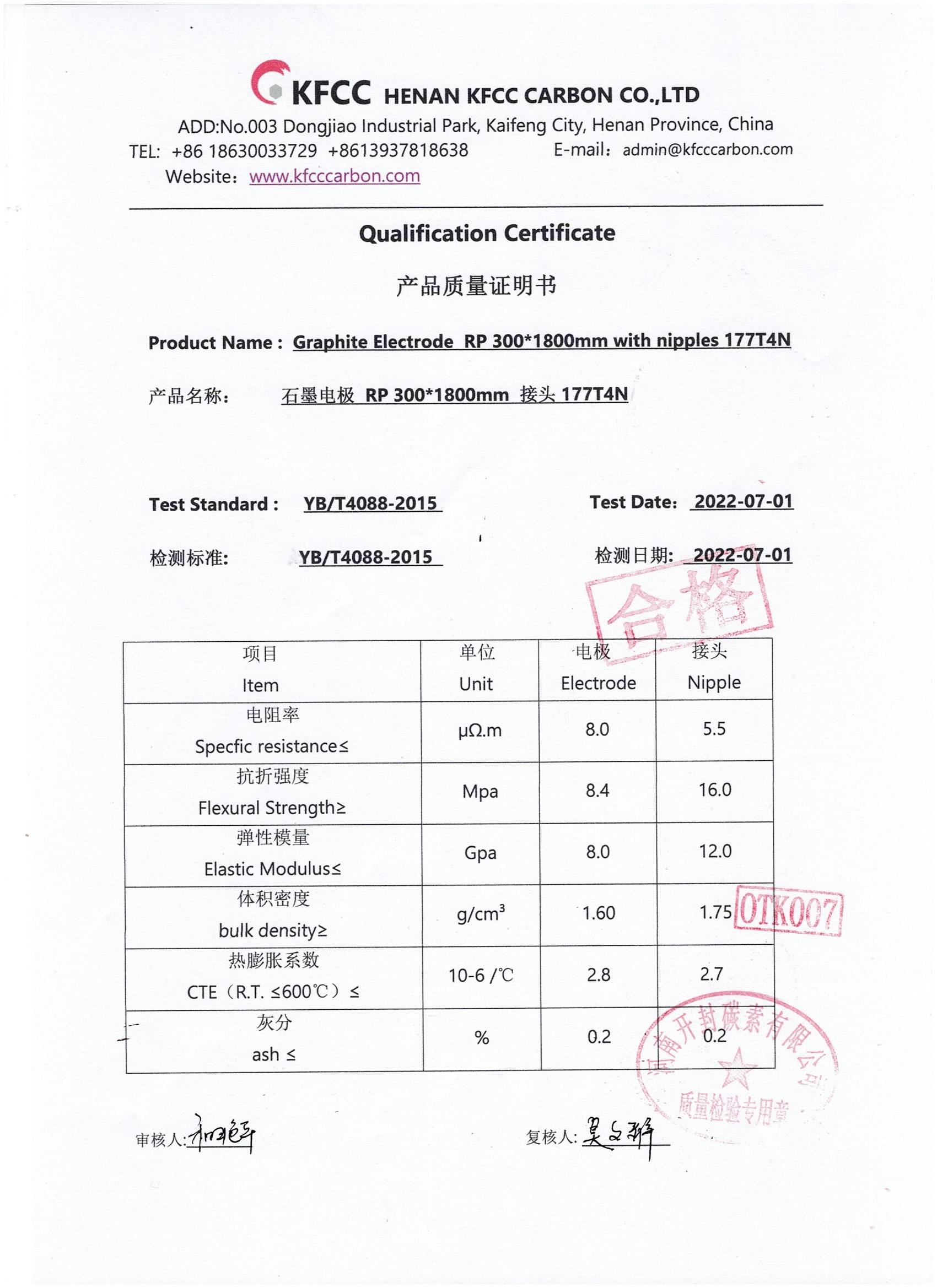

300mm RP Graphite Electrode

Graphite electrode can also be called artificial graphite electrode, refers to petroleum coke, needle coke as raw material, coal pitch as binder, after raw material calcination, crushing grinding, batching, mixing, molding, roasting, impregnation, graphitization and mechanical processing and made of a high-temperature graphite conductive material.

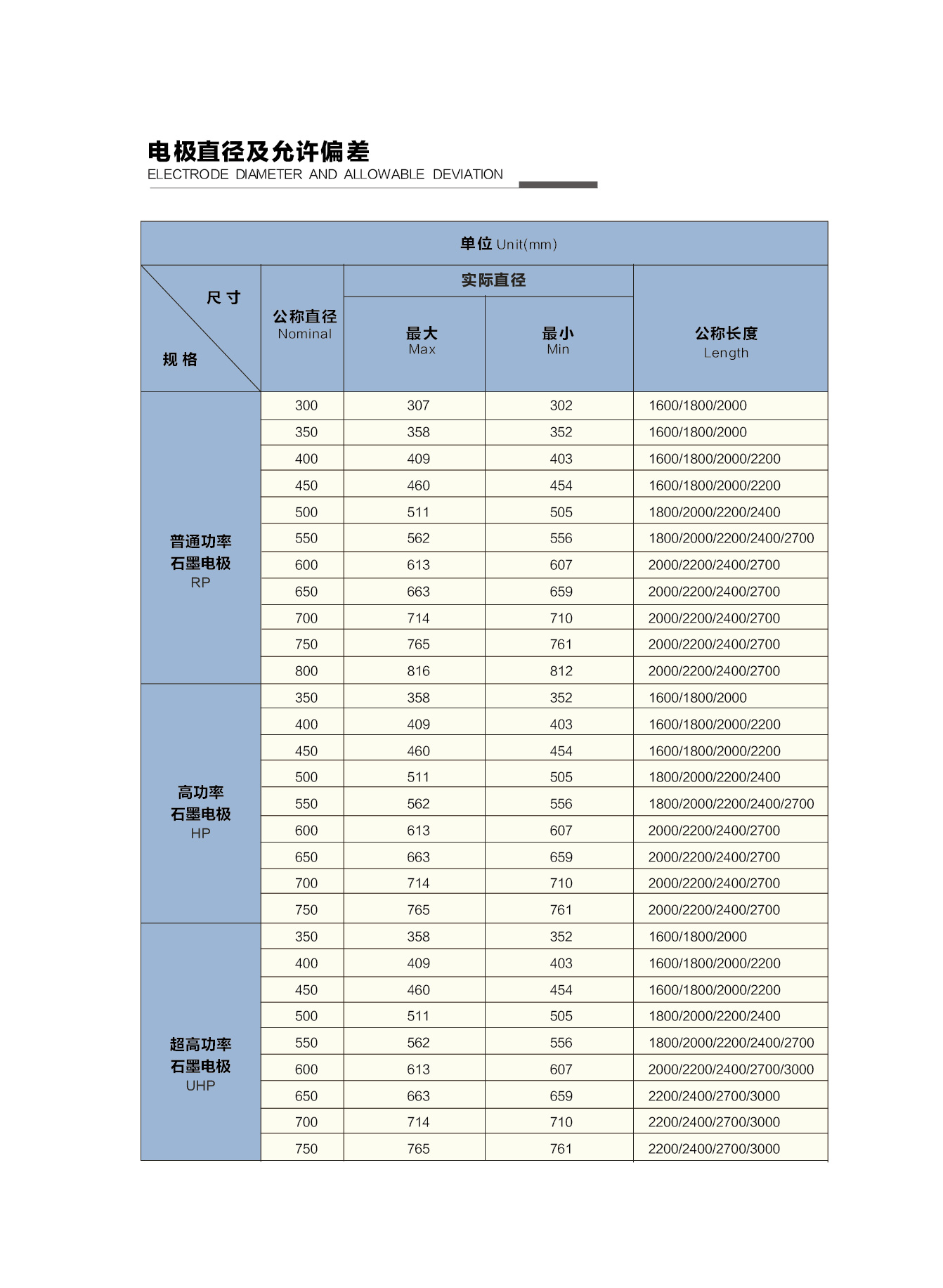

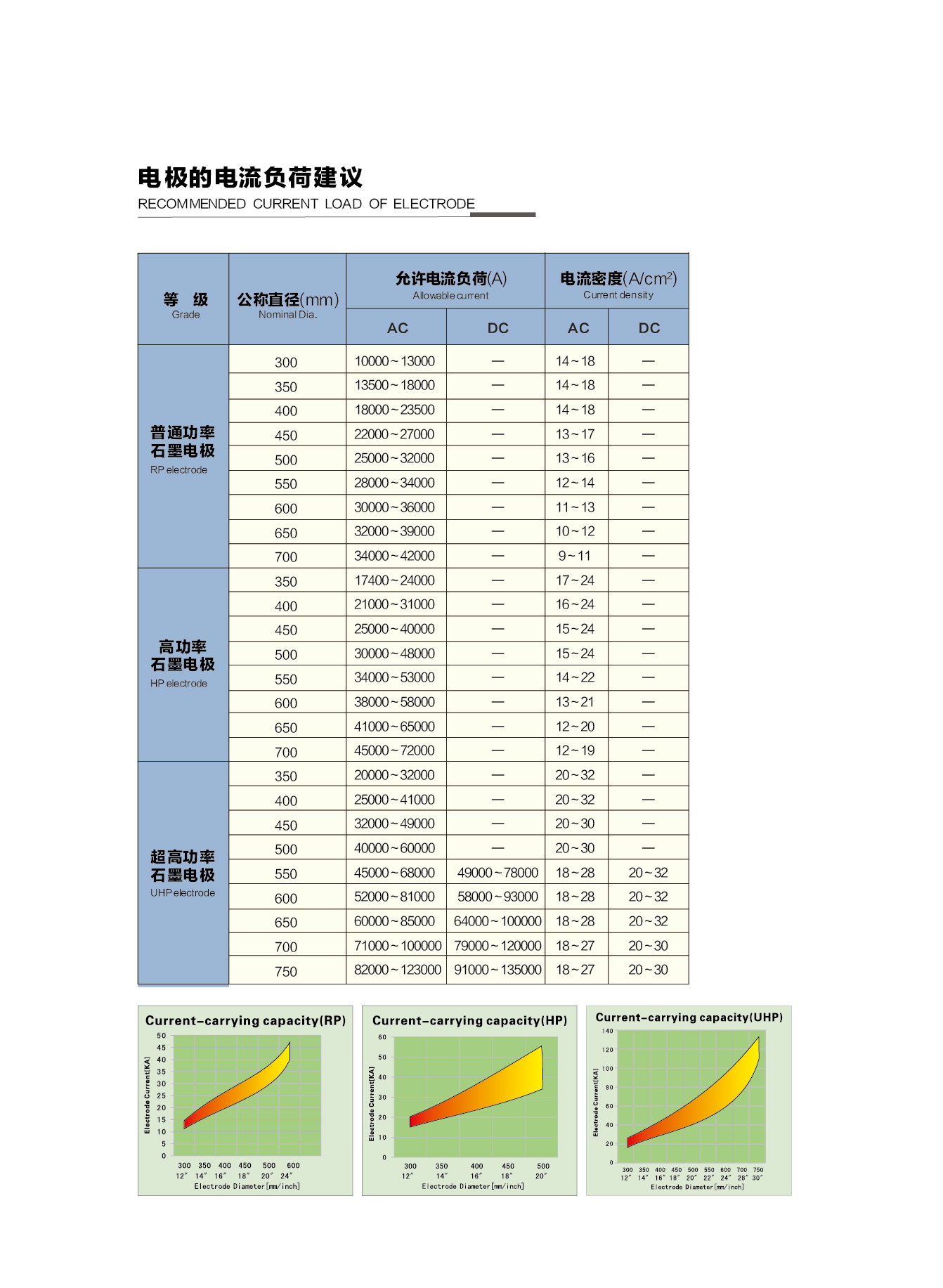

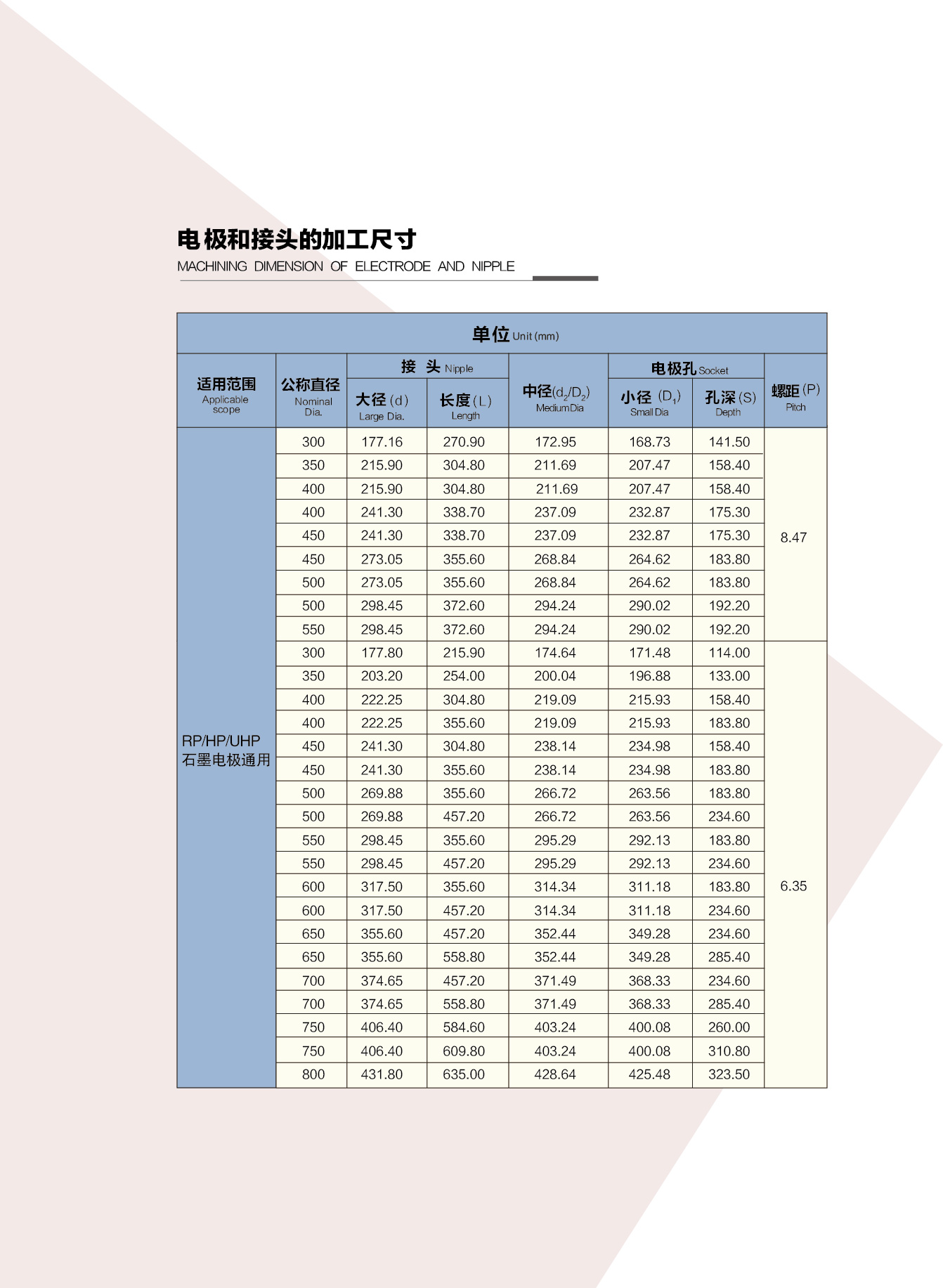

According to the difference of raw materials and physical and chemical indicators of finished products, graphite electrodes are divided into ordinary power graphite electrode (RP), high power graphite electrode (HP) and ultra-high power graphite electrode (UHP).

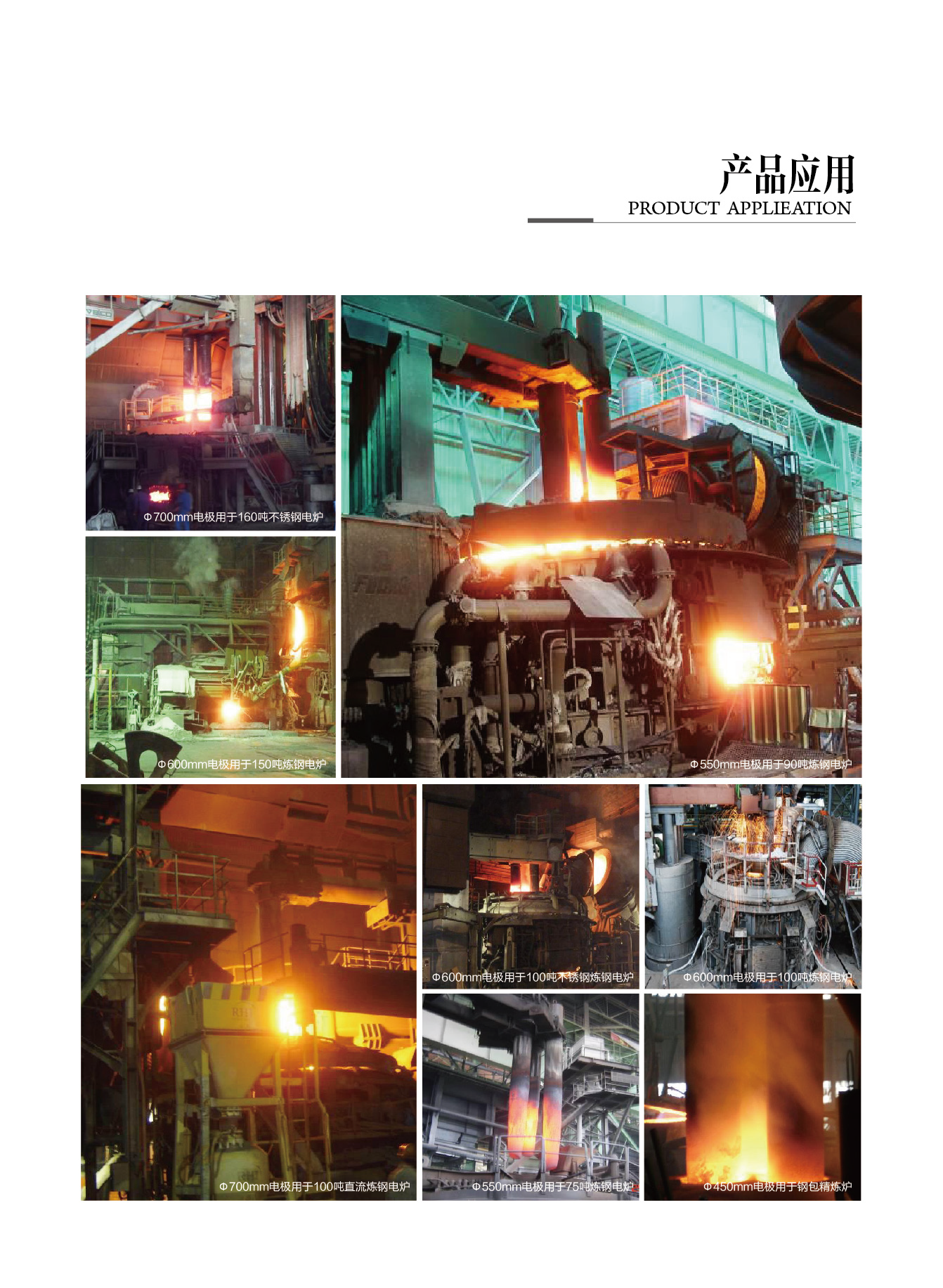

300mm RP Graphite Electrode applications

(1) Electric furnace steelmaking is a large user of graphite electrode. The output of eAF steel in China accounts for about 18% of the output of crude steel, and the graphite electrode used in steelmaking accounts for 70% ~ 80% of the total amount of graphite electrode. Electric furnace steelmaking is the use of graphite electrode into the furnace current, the use of electric extremes and charge between the arc generated by the high temperature heat source to smelting.

(2) Used for mineral thermal electric furnace mineral thermal electric furnace is mainly used for the production of industrial silicon and yellow phosphorus, which is characterized by the lower part of the conductive electrode buried in the charge, forming an arc in the charge layer, and using the heat energy emitted by the resistance of the charge itself to heat the charge, which requires higher current density mineral thermal electric furnace needs graphite electrode.

(3) For resistance furnace

The graphitization furnace for the production of graphite products, the melting furnace for melting glass and the electric furnace for the production of silicon carbide belong to the resistance furnace. The material in the furnace is both the heating resistance and the heating object. Usually, the conductive graphite electrode is embedded in the furnace wall at the end of the resistance furnace, and the graphite electrode is used for the discontinuous consumption here.

(4) For the preparation of special-shaped graphite products

The blank graphite electrode is also used for processing various crucible, mold, boat and heating body and other special-shaped graphite products.

How do graphite electrodes work?

Many steel mills use the electric arc furnace method to make iron. Ironmaking is recovered by melting scrap iron in an electric arc furnace. It is the graphite electrodes in the furnace that actually melt the iron. High density graphite electrodes have high thermal conductivity and are very heat and shock resistant. They also have low resistance and can conduct the large currents needed to melt iron.

As a leading regular power electrode supplier, KFCC provides RP/HP/UHP graphite electrodes with a diameter of 75-700mm or customized according to your needs. With on-demand product design and manufacturing and careful after-sales service, our uhp electrodes have gained high reputation from customers all over the world like America, Australia, Europe,Mid East and Africa etc. Welcome to contact us for more information!

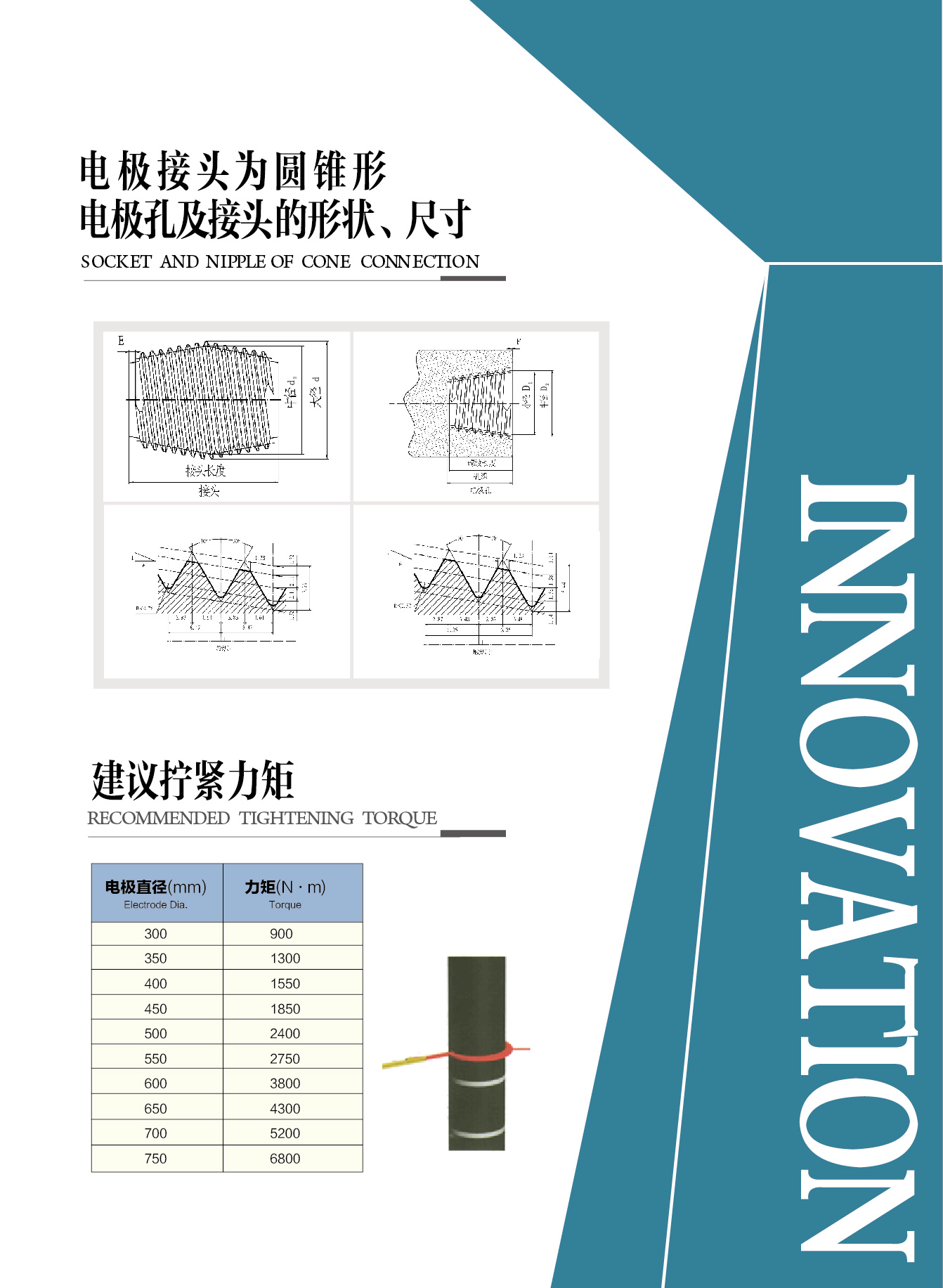

Operation guide

1. Keep the electrode clip inside the safety wire during operation.

2. Be careful not to damage the thread during loading, unloading and sending.

3. When choosing carbon graphite electrodes, please refer to the current load and density.

4. Keep away from rain, snow and water during transportation and storage, and the graphite electrode should be dry before use.

5. Compressed air is required to remove the dust on the threads before connection, to ensure that the joint and graphite electrode are properly tightened.

6. If an iron nozzle is used to hoist the electrode, please ensure that the iron nozzle thread is not deformed, so as not to damage the electrode thread.

7. In order to prevent the electrode from breaking from the scrap, the electrode should be up and down according to the melting situation, and the unmelted scrap should be pushed into the furnace.

Havw an inquiry

Follow us on social media

©2021 Henan KFCC Carbon Co.,Ltd. all rights reserved

What We Offer

Contact Info

EMAIL:

Cellphone:

+86-18831976760 / +86-13930977267

Address:

No.003 Dongjiao Industrial Park, Kaifeng City, Henan Province, China(Mainland)

admin@kfcccarbon.com

admin@kfcccarbon.com

+86-18831976760

+86-18831976760